|

|

Number 41 - selected article

|

|

|

|

Number 41 - selected article

|

|

JOHN

DICKINSON AND THE BRANDYWINE

A

Hertfordshire invention goes west

A

J Ward

The first paper mill

in the State of Delaware USA was founded in 1787 by Joshua Gilpin (1765-1841).

It was sited on the Brandy-wine River near Wilmington. At that time paper making

was a manual process, the chief tool of the trade being the paper mould; a

rectangular frame covered with fine wire gauze. Paper was made by immersing the

mould in a vat of dilute pulp of rag fibres and lifting it out again in such a

way that the fibres deposited on the gauze formed a sheet of wet paper. This was

then turned out on to a felt and dried.

In 1817 Thomas Gilpin,

Joshua's younger brother, produced paper "in an endless length" on a

machine which he had built. It had been patented by him in 1816 and was the

first paper machine in the United States. It bore a remarkable similarity to

John Dickinson's machine which had been patented in England in 1809. This was no

coincidence.

To follow the chain of

events which links the two patents it is necessary to go back to what is known

today as Apsley End, Hemel Hempstead, at the end of the eighteenth century.

Apsley

Mill, situated on the river Gade, was one of many mills converted from flour

milling to paper making in the second half of that century. Paper was being made

there by 1774, when Roger Greatrake was the occupier. He took out a Sun Fire

Insurance on the mill in 1778 and the same year his name appeared on the Hemel

Hempstead militia list described as "gentleman", while Laurance

Greatrake was registered as "paper maker". Laurance was on the Kings

Langley militia lists from 1781 to 1785 as "paper maker" and latterly

as "gentleman", and then in 1786 as "Mr Greatrake junior, paper

maker". A road map published in 1790 by J Gary shows Mr Grettorix at Apsley

Mill - just one of several variations of Greatrake in the records.

In

1792. Roger Greatrake was a witness at the wedding of Mary Ann Greatrake, aged

26 of Kings Langley, and the Revd. Joseph Hamilton, curate of Hemel Hempstead.

Four years later Roger was buried at Kings Langley. At Hemel Hempstead on 26th

December 1799, Laurance's children were baptised: Eliza, Charles Laurance,

George, Marianne and Henry Joseph. By January 1800, George Stafford was making

paper at Apsley Mill.

John

Dickinson (1782-1869) served an apprenticeship and then set up as a stationer in

London in 1804. Even before his

apprenticeship finished he was experimenting with a machine to make paper. It

was his own invention which he patented in 1809. Basically it comprised a hollow

perforated brass cylinder covered with a fine wire mesh partly immersed in a vat

of pulp in which it rotated, picking up fibres to form a wet sheet which was

taken off at the highest point on a wet felt. Dickinson's machine became known

as the cylinder mould or vat machine. Confident in himself and his invention,

John Dickinson bought Apsley Mill from George Stafford in 1809. He married a

local banker's daughter,, Ann Grover, in 1810, and the following year acquired

nearby Nash Mill, where paper had been made by hand for some 40 years.

At

that time, about half a mile up the Gade at Frogmore Mill and Two Waters Mill,

paper was already being made by machines of a different type. By this method

diluted pulp flowed onto a moving continuous wire gauze so that, as the water

drained away, a wet sheet of paper was formed which was taken off the wire after

a short run by an endless felt.

It

was Nicolas Louis Robert, working in a paper mill at Essonnes, France, who first

constructed such a machine,

which he patented in France in 1799. In the aftermath of the French

Revolution and with France at war, conditions were not right for the development

of the machine in France. Plans and a model machine, or the essential parts of

it, were brought to England where the wealthy stationers Henry and Sealy Fourdrinier,

who were already established hand-made paper makers in this country, turned it

into a mechanical and commercial success with the help of engineering genius

Brian Donkin. Sadly, the cost forced the Fourdrinier brothers into bankruptcy.

An

improved Robert model was installed at Frogmore Mill which the Fourdriniers had

bought specially for that purpose in 1803. A brand new and improved machine

constructed by Donkin at his Bermondsey Works, which was the first commercial

paper machine, was installed there the following year. In 1805, a larger machine

was erected at the Fourdriniers' Two Waters Mill, where they had made paper by

hand since 1791.

Brian

Donkin built and sold Fourdrinier machines with an agreement that the users paid

an annual royalty to the Fourdriniers, so it soon came into fairly general use.

It was not until 1827, however, that the first Fourdrinier machine was sent to

the USA. John Dickinson, on the other hand, did not seek to exploit his patents

by selling rights or machines; in fact he did his best to keep his techniques

secret. Although Dickinson's inventions were patented in England, that gave no

protection in America.

The

man who made it possible for Thomas Gilpin to construct his cylinder machine was

Laurence Greatrake. This is made quite clear by George Escol Sellers, who in his

reminiscences tells of a meeting with John Dickinson in 1832.

"Mr

Dickinson asked me if I had ever met a Mr Greatrake in America, who many years

before had been taken from him by Mr Thomas Gilpin offering a higher salary than

he could at the time afford to pay. On my replying in the affirmative, and that

I was well acquainted with Gilpin and thoroughly posted as to his cylinder paper

machine, he then spoke of Greatrake as having been one of his most reliable and

trusted employees; that it was a severe blow his leaving at the time he did

knowing that he had taken with him to introduce in the States his invention,

that they had together worked on for years, through great difficulties. He was

very bitter on Gilpin for, as he called it, 'buying Greatrake to get his

inventions'. "

Joshua

and Thomas Gilpin, who ran the Wilmington paper mill, were determined to keep

abreast of developments in paper making, and to that end Joshua visited Europe

between 1795 and 1801, visiting Nash Mills and Greatrake's Mill (ie. Apsley

Mill) in 1796 and between 181 I and 1815. In this country he met many of the

paper making pioneers including the Fourdriniers, Dickinson and Donkin, and his

observation of industrial processes, not just paper making, were recorded in

detail in a journal of many volumes. If, as stated earlier, Dickinson and

Greatrake had worked together for years, then it must have been during Gilpin's

second visit that Greatrake was persuaded to go to America and become manager of

the Gilpin mills.

Sellers

goes on to write,

"The

Gilpin machine was that of John Dickinson. The original cylinder was made in

England and brought out by Greatrake.... My

impression is that the rest of the machine was constructed at a machine shop

erected for the purpose at the mill. For many years the machine was worked with

as much secrecy as Dickinson had worked his in England".

The

Gilpin Mills did not prosper for long. The last paper was made there in

1837,just 50 years after it had opened.

The

advantage Dickinson's machine had over the Fourdrinier in the early days was

that it produced a smooth sheet of paper with only a slight wire-mark on the

underside, making it even-sided and very suitable for book printing. It is worth

noting, however, that by the time the Gilpin machine was in production Dickinson

was also using Fourdriniers in his mills. Despite the early introduction of the

cylinder machine in America it was the Fourdrinier which became the world's

paper-making machine. However, one of John Dickinson's cylinder machines

installed at his Croxley Mill when it opened in 1830, continued to run until

1930. One of its specialities was thin paper for bible and hymnal printing.

The

advantage Dickinson's machine had over the Fourdrinier in the early days was

that it produced a smooth sheet of paper with only a slight wire-mark on the

underside, making it even-sided and very suitable for book printing. It is worth

noting, however, that by the time the Gilpin machine was in production Dickinson

was also using Fourdriniers in his mills. Despite the early introduction of the

cylinder machine in America it was the Fourdrinier which became the world's

paper-making machine. However, one of John Dickinson's cylinder machines

installed at his Croxley Mill when it opened in 1830, continued to run until

1930. One of its specialities was thin paper for bible and hymnal printing.

Dickinson's

machine, originally patented in 1809 was further developed by patents of 1817

and 1830 for the production of duplex paper from two cylinders. This established

the principle of amalgamating several layers of pulp for board-making. Up until

the late 1970s, board-making machines were based on Dickinson's original

principle.

Another

of John Dickinson's inventions was the modification of his cylinder machine to

incorporate fine threads such as silk into the paper as it was made, thus

providing protection against forgery. This paper was used for Exchequer Bonds

and the like. With the introduction of the 'Universal Penny Post', Dickinson's

security paper, made on two machines at his Nash Mills, was used exclusively for

the Mulready envelopes and sheets of 1840, and, for a while, for the embossed

envelopes which replaced them. It was also used for the 10d.and one shilling

stamps of 1847.

The

firm John Dickinson established went from strength to strength for well over 150

years, as both paper makers and manufacturing stationers. Today, a relatively

small but modern factory produces stationery on part of the Apsley site,

perpetuating the name John Dickinson, one of the most successful machine paper

making pioneers.

SOURCES

Eric

Thomas Finerty. The History of Paper Mills in Hertfordshire

Hertfordshire

County Records Office

Joan

Evans. The Endless Web

A J Ward.

The Early History of Machine Paper-Making

B G

Watson. John Dickinson and His Paper Machine: The Paper Maker Vol 36 No 1

1967, Hercules Inc., USA

A

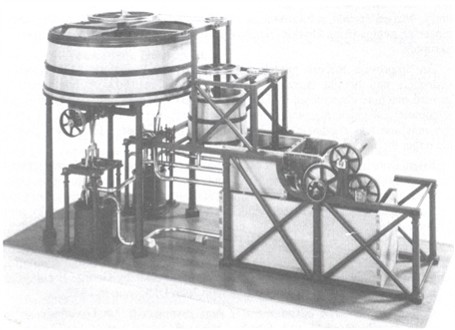

mode! of John Dlckinson's cylinder paper-making machine constructed m the

Science Museum's workshops from the original patent specification to mark

the bi-centenary of his birth. (Published by kind permission of the Science

Museum)